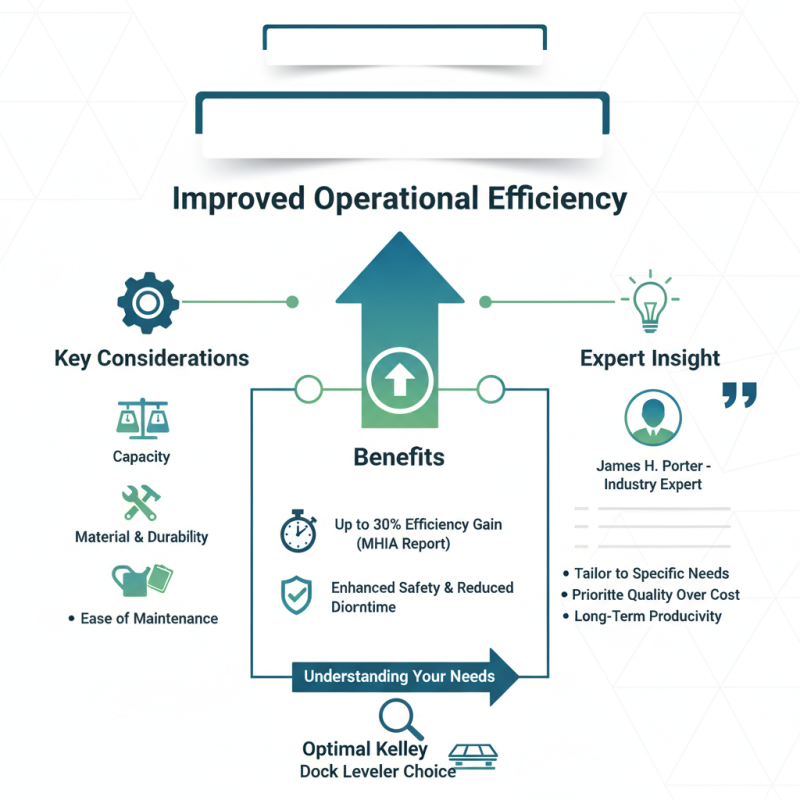

In the ever-evolving logistics industry, choosing the best Kelley dock leveler is crucial for operational efficiency. According to a recent report by the Material Handling Industry Association (MHIA), the right dock leveler can improve loading dock efficiency by up to 30%. This highlights the importance of understanding various models and features.

Industry expert, James H. Porter, emphasizes, "Selecting the right Kelley dock leveler can significantly impact your overall productivity." His insights remind us that not all dock levelers are created equal. Factors such as capacity, material, and ease of maintenance should guide your choice.

However, many companies overlook these essential features. They may prioritize cost over quality. This can lead to increased downtime and safety issues. Thus, investing time in understanding your specific needs is vital. The right leveler not only enhances performance but also ensures safety at the dock.

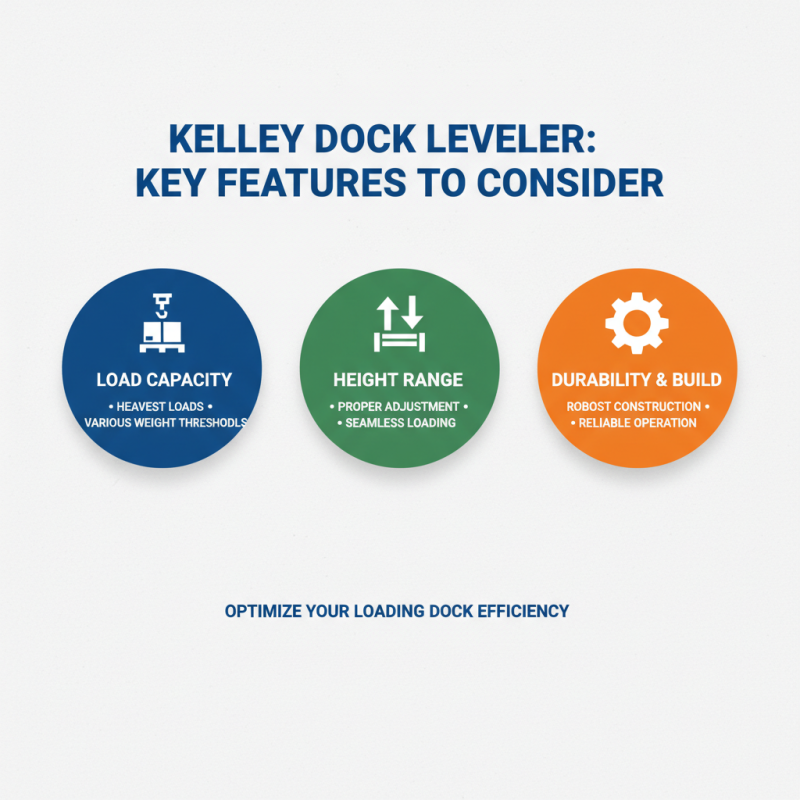

When choosing a Kelley dock leveler, several key features stand out. Load capacity is essential. Make sure it can handle the weight of your heaviest loads. Look for options that support various weight thresholds. Consider the height range too. Proper height adjustment is crucial for seamless loading and unloading processes.

Durability is another important factor. A well-constructed leveler can withstand constant use. Check materials used in its construction. Steel options may offer greater longevity than others. Safety features are essential as well. Ensure it comes with proper edge protection and non-slip surfaces.

Maintenance should also be considered. An easy-to-service design can save time. Look for models that allow for quick inspections and repairs. It is often overlooked, yet this can significantly reduce downtime. Choose wisely, as not all features may suit every environment. Optimal performance hinges on thoughtful consideration of these traits.

Choosing the right dock leveler is critical for efficient loading and unloading. When considering load capacity, assess your typical cargo weight. Heavy shipments may require higher capacity options. Ensure the leveler can handle peak loads to avoid failures. Users often underestimate the importance of load ratings, leading to potential mishaps.

Durability is another essential aspect. Look for levelers made from robust materials that can withstand constant use. Seasonal changes can affect materials. Corrosion from water or chemicals can weaken the structure over time. Routine maintenance is vital for ensuring longevity. Small issues should not be ignored.

**Tips:** Always check the manufacturer's specifications. Conduct regular inspections to identify any wear and tear. Testing load capacity under various conditions is advisable. You might be surprised by the results. Consider the installation environment, as it affects usability. It’s not just about numbers; real-world performance matters.

When choosing a dock leveler, safety features should be a top priority.

These features significantly enhance operations and protect both equipment and workers. Look for levelers that offer safety barriers or edge guards.

These elements can prevent accidents and improve workplace safety.

Additionally, consider models with audible alarms. An alarm alerts workers when the leveler is in use. This simple feature can reduce the risk of injuries during busy loading and unloading times.

Regular maintenance is crucial. Inspect safety features regularly to ensure they function correctly. Neglecting maintenance can lead to unforeseen risks.

User feedback is essential. Gather insights from current users about their experiences. Some may have faced issues with safety features that need addressing.

This reflection can guide your choice. Every decision matters, especially in safety. Investing in the right dock leveler protects lives and enhances productivity.

Don’t overlook these key considerations. They are vital for smooth operations.

Choosing the right dock leveler can significantly impact operational efficiency. Different types of dock levelers serve unique purposes and environments. For instance, hydraulic dock levelers are known for their smooth operation. According to industry reports, 40% of warehouses prefer hydraulic models due to their ease of use and durability. They can withstand heavy loads, making them ideal for high-traffic areas.

Mechanical dock levelers, on the other hand, are cost-effective and require minimal maintenance. However, they may struggle with heavier loads. In a recent survey, 35% of operations reported performance issues when using mechanical systems for overly demanding tasks. User feedback indicates a need for caution when selecting these models. Additionally, edge-of-doc levelers provide a solution for uneven surfaces, contributing to safer loading operations. This variety highlights the importance of understanding your specific needs.

Different types of materials used also affect functionality. Steel levelers typically offer higher longevity compared to aluminum options. However, they may be heavier and more challenging to operate. Many companies overlook this when making choices, resulting in dissatisfaction later on. Balancing cost, capacity, and functionality is crucial to avoid potential inefficiencies in the future.

| Type of Dock Leveler | Weight Capacity | Platform Size | Operational Method | Best Use Case |

|---|---|---|---|---|

| Hydraulic Dock Leveler | 30,000 lbs | 6' x 8' | Hydraulic | High Volume Shipping |

| Mechanical Dock Leveler | 25,000 lbs | 7' x 10' | Manual | Smaller Operations |

| Air-Powered Dock Leveler | 20,000 lbs | 6' x 10' | Air Pressure | Intermediate Use |

| Vertical Dock Leveler | 15,000 lbs | 5' x 7' | Electric | Limited Space Situations |

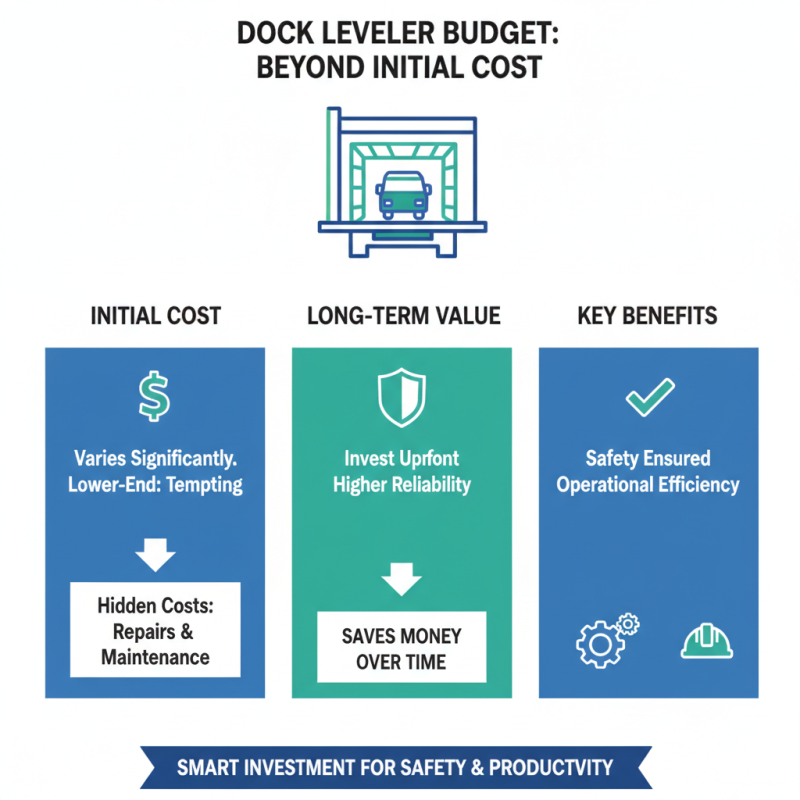

When budgeting for a dock leveler, it's essential to assess initial costs carefully. Prices can vary significantly. You might find lower-end models tempting. However, these often come with hidden costs. Repair and maintenance need to be factored in. Investing more upfront can save you money in the long run. A reliable dock leveler will ensure safety and efficiency.

Moreover, consider the operational costs. Energy-efficient models may have a higher purchase price. Yet, they can reduce electricity bills over time. Analyze your facility's usage patterns. This can influence your decision. It’s easy to overlook future expenses when focusing solely on the purchase price. Doing proper research can yield better long-term outcomes.

Don’t forget to explore financing options. Leasing could reduce upfront costs, making it easier to acquire quality equipment. However, be cautious; monthly payments can accumulate. Reflect on whether you prefer ownership or short-term flexibility. Balancing immediate needs with future goals is vital. The decisions made now can affect your budget for years.