Loading dock solutions play a crucial role in efficient supply chain management. According to a report by the Logistics Management Institute, optimizing loading dock operations can increase productivity by up to 30%. This statistic highlights the importance of having the right systems in place. Industry expert John Smith states, "Effective loading dock solutions are essential to minimize delays and ensure smooth operations."

Many businesses overlook their loading dock designs and technologies. This can lead to inefficiencies, increased costs, and lost opportunities. A well-planned loading dock can enhance safety and streamline processes. However, not all solutions fit every business. It’s important to analyze specific needs and challenges.

The variety of loading dock solutions available ranges from basic equipment to advanced technology integrations. While many options exist, choosing the right one requires careful consideration. Investing in the wrong solution can hinder workflow. Balancing cost and functionality is often a difficult task. This is why understanding and evaluating loading dock solutions is vital for any business aiming to thrive in today’s competitive environment.

Loading dock solutions play a crucial role in the operational efficiency of businesses. They are the bridge between storage and transportation. A well-designed loading dock can improve workflow, reduce loading times, and enhance safety. According to a recent industry report, inefficient loading dock operations can lead to a productivity drop of up to 30%. This statistic underscores the importance of investing in optimal loading dock solutions.

Businesses often overlook the necessity of proper loading dock equipment and layout. Many facilities face logistical challenges due to outdated systems. In fact, a survey found that 25% of companies reported injuries linked to poorly designed loading areas. These injuries could lead to costly insurance claims and diminished employee morale. Transitioning to modern loading dock solutions can mitigate these risks. They offer safety features like auto-leveling ramps and real-time monitoring systems. Yet, not all businesses fully utilize these advanced technologies.

The financial implications are significant. Poor loading dock practices can increase shipping costs and extend delivery times. Effective solutions can reduce these expenses considerably. One study revealed that implementing better loading dock management could cut shipping costs by as much as 15%. This is a crucial detail for businesses seeking to improve their bottom lines. Investing in such solutions feels daunting, but the potential savings and safety improvements warrant careful consideration.

This chart illustrates the efficiency ratings of various loading dock solutions across different industries. The ratings are based on a scale of 0 to 100, reflecting how effectively loading docks in each sector operate. Higher ratings indicate better performance, contributing to smoother logistics and operations.

Loading docks are crucial for efficient supply chain operations. They serve as the main interface between transportation and warehouse activities. Understanding the types of loading dock solutions available can significantly impact productivity and safety. According to a report by the Material Handling Industry of America, nearly 70% of logistics costs arise from inefficient loading and unloading processes.

There are several loading dock solutions to consider:

When evaluating choices, consider specific business needs. A perfect solution does not exist. Each type has its pros and cons. For instance, while some solutions may maximize efficiency, they may lack durability. Flexibility is paramount, as industry demands can shift. Being aware of every option helps businesses make informed decisions for their loading dock systems.

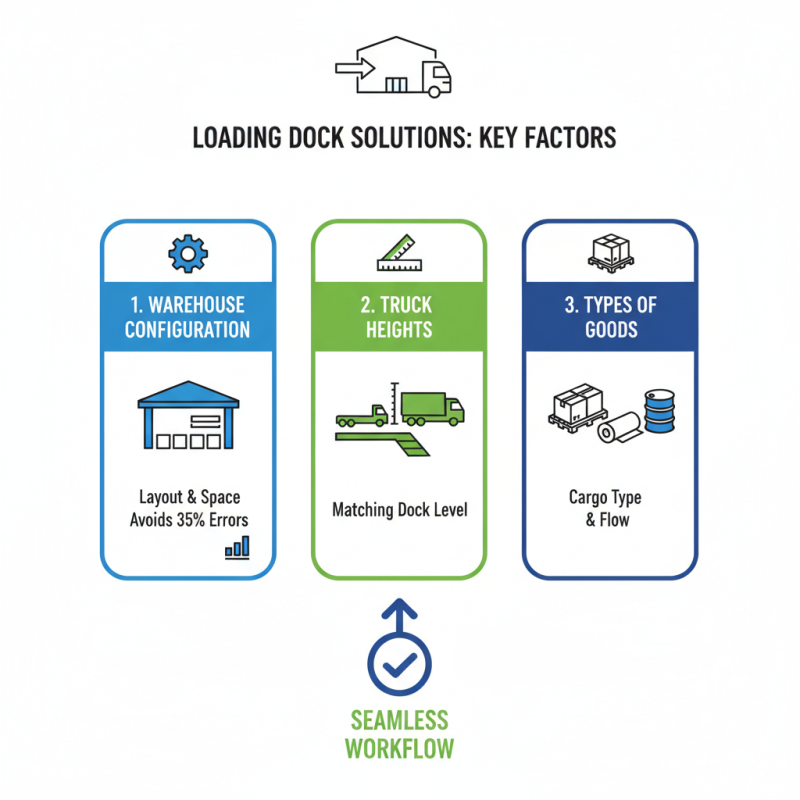

When selecting a loading dock solution, several key factors should be evaluated. Understanding the warehouse configuration is crucial. A report by the Warehouse Technology Association states that 35% of logistics errors are due to improper loading dock design. Consider the height of your trucks and the type of goods you handle. This ensures a seamless workflow.

Another important factor is the equipment's durability. These solutions often face heavy wear and tear. In fact, 25% of loading dock injuries stem from improper equipment use. Regular maintenance of dock levellers and seals can prevent costly accidents. A comprehensive safety protocol is also needed. Training your staff reduces risks and improves efficiency.

Energy efficiency is an emerging concern. The Department of Energy notes that 70% of warehouses can reduce energy consumption by optimizing their loading docks. Implementing tech solutions can enhance performance and tracking. However, continuous assessment is necessary. Choosing the right technology involves weighing initial costs against long-term savings. Your loading dock should evolve with your business needs.

Modern loading dock technologies can greatly enhance efficiency in your business operations. These solutions streamline the process of loading and unloading goods.

For example, automated dock levelers adjust automatically to varying truck heights. This speeds up the loading process and reduces the risk of injuries. Employees can work more safely and quickly, leading to higher productivity.

Another key benefit is real-time inventory tracking. Integrated systems allow businesses to monitor stock levels without manual checks. Sensors can detect when items are loaded or unloaded, providing accurate data instantly. This reduces errors and improves decision-making. However, integrating new technology can be challenging. Training staff on new systems takes time and effort. Some employees may resist changes, preferring old methods.

Despite these hurdles, the long-term gains are significant. Improved communication between dock workers and drivers leads to smoother operations. Enhanced data analytics can reveal trends and inefficiencies, prompting necessary adjustments. Embracing modern loading dock solutions may initially seem daunting, yet the potential benefits are worth exploring.

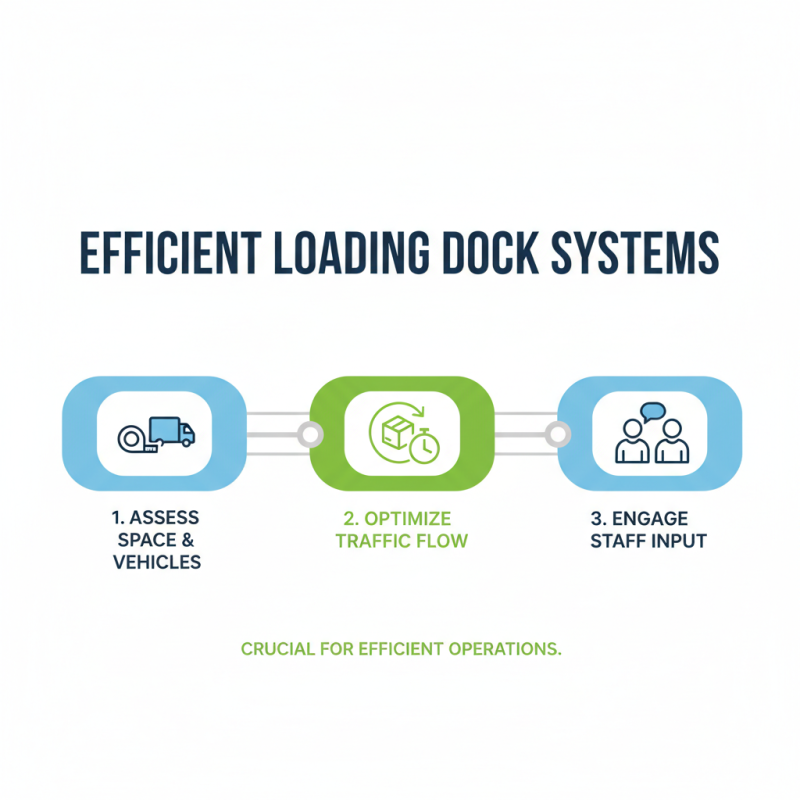

Loading dock systems are crucial for efficient operations. Implementing these systems involves careful planning. Start by assessing the space and the types of vehicles used. Each dock should have sufficient room for loading and unloading. Monitor traffic flow to prevent bottlenecks. It’s essential to engage staff in this process. Their input can highlight potential issues early on.

Regular maintenance is key to longevity. Schedule routine inspections to identify wear and tear. Lubricate joints and replace damaged parts immediately. Staff should be trained to conduct preliminary checks. Small problems can escalate if ignored. Consider a checklist for daily inspections. It’s easy to overlook details when busy, but vigilance pays off.

Adaptation is necessary as business evolves. Changing inventory types may require modifications to the dock. Flexibility in design can save money later. Listen to feedback from employees about the system's functionality. It’s a mix of daily operation and strategic planning. Not every decision will be perfect, and that's okay. Reflecting on what works and what doesn’t ensures continuous improvement.