Choosing the right Serco dock leveler parts is crucial for efficiency. Industry expert John Smith notes, "The right part can make all the difference." Dock levelers play a significant role in loading and unloading. The correct parts ensure safety and functionality.

When it comes to Serco dock leveler parts, considerations include size, weight capacity, and application needs. Even small miscalculations can lead to operational issues. It's important to look at each component with care. Overlooked parts can cause delays and increase costs.

Each dock facility is unique. Custom solutions are often necessary. Don't settle for generic options. Your specific needs might warrant special features or materials. Investing the time to choose wisely could prevent future headaches. Reflecting on this can lead to better performance and reliability.

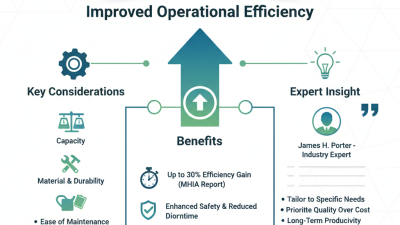

When selecting dock leveler parts, understanding the types available is crucial. There are various components to consider: hydraulic systems, control boxes, and bumpers. Each plays a unique role in ensuring effective operations. The right hydraulic system can enhance efficiency by up to 20%, according to industry reports. These systems operate under different load demands, which influence their choice.

Control boxes are another key area. They may vary in design and functionality. A well-designed control system can minimize wear and tear, extending the life of your dock leveler. Research indicates that proper maintenance can reduce downtime by nearly 25%. However, many operators overlook this aspect, leading to unexpected failures.

Bumpers offer protection and stability. However, selecting the correct material is essential. Different environments require different types. Durable rubber bumpers withstand heavy impact, while softer ones are best for lighter use. It's easy to ignore these details, but poor choices may cost more in the long run. Properly assessing your needs can save you time and money over time.

Choosing the right dock leveler parts is crucial for efficiency. Several factors must be considered during this process.

First, assess the load capacity required by your operations. Heavy loads require stronger components.

For lighter applications, standard options may suffice.

Another critical factor is the environment.

Indoor and outdoor settings have different needs.

Corrosion resistance is vital for outdoor use. Temperature variations also affect material choice.

Tips: Always verify compatibility with your existing equipment.

Mismatched parts can lead to breakdowns.

It's also wise to consult users with similar setups. They can provide valuable insights.

Lastly, consider the warranty and support options. Protect your investment in the long run.

When evaluating dock leveler parts, compatibility is crucial. Start by examining your existing equipment. Check the model and specifications. Look for any signs of wear or previous modifications. Your new parts must align perfectly. Otherwise, performance could suffer.

Consider the weight and capacity needs of your dock. An insufficient part could lead to safety hazards. Ensure that any new component can handle the load. Sometimes, it’s easy to overlook the small details. A minor mismatch can cause frequent failures.

Always refer to component dimensions and installation methods. Sometimes, you may find recommended parts that don’t seem ideal. It’s tempting to go for cheaper options, but this can lead to issues. Investing in the right parts saves time and reduces headaches long-term. Take the time to analyze your choices carefully. Building a solid foundation leads to smoother operations.

When choosing parts for your dock leveler, assessing quality is crucial. Durable parts ensure reliable performance. High-quality materials resist wear and tear, extending the lifespan of your dock leveler. Look for components made from robust metals or reinforced plastics. These materials can better withstand heavy usage. Visual inspection can reveal a lot. Check for signs of rust or structural flaws.

Durability is equally important. Parts that wear out quickly can lead to operational issues. Frequent replacements are costly and inconvenient. Consider the manufacturer’s reputation and user reviews. Feedback can highlight potential issues. However, be cautious. Not all opinions reflect the actual performance.

Sometimes, it’s easy to overlook the details. Seals and gaskets may seem minor but play a significant role. A small flaw can lead to costly repairs down the line. Prioritize these components as well. Make sure every part complements the others. Take the time to research and reflect on your choices. Choose wisely for long-lasting solutions.

| Part Type | Material | Weight Capacity | Durability Rating | Warranty Period |

|---|---|---|---|---|

| Hydraulic Cylinder | Steel | 25,000 lbs | High | 2 years |

| Control Panel | Aluminum | N/A | Medium | 1 year |

| Dock Leveler Lip | Rubber | 10,000 lbs | High | 3 years |

| Leveling Mechanism | Composite | 20,000 lbs | High | 2 years |

| Sealing System | PVC | N/A | Medium | 1 year |

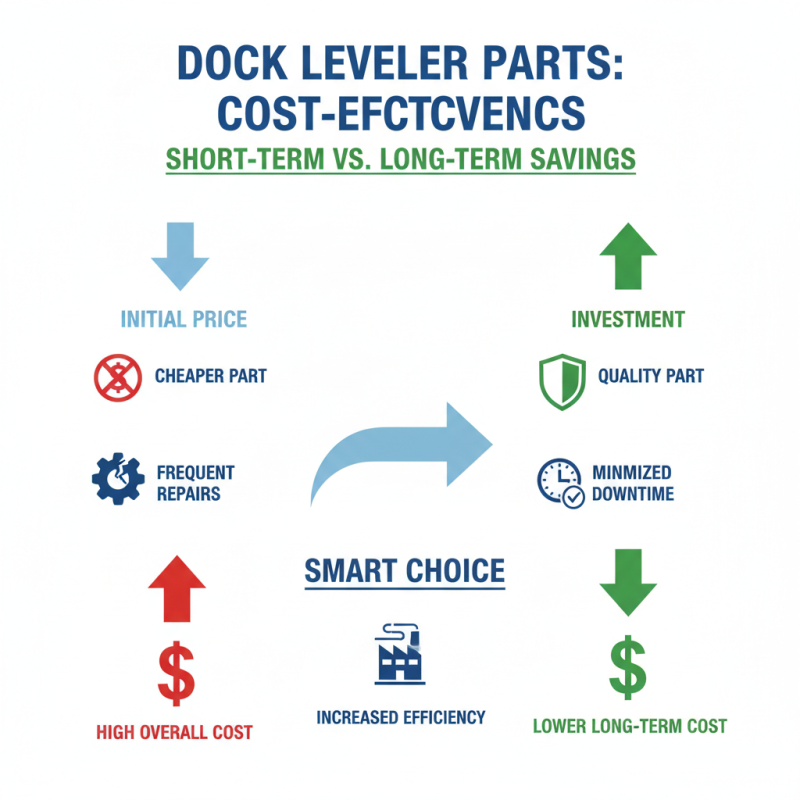

When selecting dock leveler parts, cost-effectiveness is crucial. Many people overlook the long-term implications of their choices. It's easy to fixate on the initial price. However, a cheaper part may lead to more frequent repairs. This can inflate overall costs over time. Investing a bit more initially can save money in the long run. A good part should minimize downtime and increase efficiency.

Warranty options are another vital aspect. A strong warranty reflects confidence in the product. Look beyond standard coverage. Some manufacturers offer extended warranties, which can provide peace of mind. These policies may cover wear and tear. They often include repairs or replacements at no additional cost. Understanding the warranty terms can influence your decision. It’s essential to read the fine print.

Choosing dock leveler parts is not just about cost. It's a balance between price, durability, and support. Reflect on your specific needs. Consider how often you use your equipment. How rigorous is your loading process? Getting the right part can make a difference, but think carefully about what "cost-effective" truly means. Choose wisely.