In today's dynamic logistics landscape, the efficiency of warehouse operations plays a crucial role in maintaining a competitive edge. According to the Material Handling Industry of America (MHIA), effective loading dock design can improve operational efficiency by up to 30%. A key component in optimizing these operations is the hydraulic dock leveler. These systems bridge the gap between trucks and loading docks, ensuring safe and seamless transitions for goods during loading and unloading.

As warehouses continue to evolve with increasing demands for speed and accuracy, investing in the right hydraulic dock leveler has become paramount. The global dock leveler market was valued at approximately $1.5 billion in 2022 and is projected to grow significantly, driven by the rise of e-commerce and modern supply chain practices. Understanding the features, specifications, and operational efficiency of hydraulic dock levelers not only affects the safety of handling operations but also enhances the overall productivity of warehouse practices.

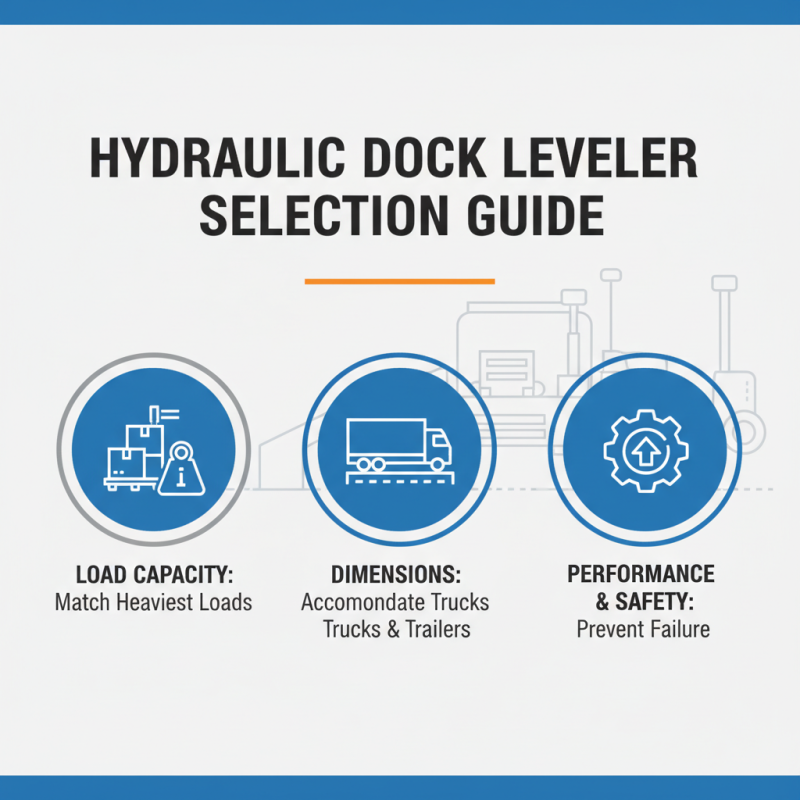

Selecting the appropriate hydraulic dock leveler requires careful consideration of various factors, including load capacities, maintenance needs, and environmental conditions. This guide aims to provide warehouse managers and facility operators with the insights needed to choose the best hydraulic dock leveler tailored to their operational requirements, ultimately supporting a more reliable and efficient supply chain process.

Hydraulic dock levelers are essential tools in warehousing operations, serving as bridges between loading docks and transport vehicles. Their primary function is to create a seamless transition for goods being loaded or unloaded, which enhances both efficiency and safety. Understanding the mechanics of hydraulic dock levelers is crucial for warehouse managers. These devices utilize hydraulic power to adjust the height of the platform, accommodating various truck heights and ensuring a stable loading surface. This functionality minimizes the risk of injury for workers and reduces the chance of product damage during transit.

The importance of hydraulic dock levelers extends beyond mere functionality; they significantly impact overall warehouse productivity. By enabling seamless loading and unloading processes, these levelers help optimize workflow, reduce wait times, and improve the speed of operations. Additionally, a well-maintained hydraulic dock leveler can contribute to a safer working environment by preventing accidents that often arise from uneven surfaces or improper loading procedures. Therefore, investing in the right hydraulic dock leveler is not just about choosing a piece of equipment, but about enhancing the operational efficiency and safety standards of the entire warehouse.

When selecting a hydraulic dock leveler for your warehouse, several key factors must be taken into account to ensure optimal performance and safety. First, consider the load capacity of the leveler. It is essential to match the leveler’s capacity with the heaviest loads that will pass through the dock. Overloading a leveler can lead to mechanical failure and increased maintenance costs, so understanding your typical load requirements is crucial. Additionally, the leveler's width and length should accommodate the dimensions of your trucks and trailers, allowing for smooth loading and unloading processes.

Another important aspect is the type of operational environment. Evaluate whether your warehouse operates in a high-traffic area or if there are specific weather-related challenges, such as extreme temperatures or moisture levels. This will influence the materials and durability of the leveler. Options with corrosion-resistant features or those designed specifically for rugged environments can enhance longevity and performance. Furthermore, consider safety features like lip extensions, sensors, and indicators that align with best practices for dock operations, ensuring the safety of personnel and equipment throughout the loading process.

When selecting the appropriate hydraulic dock leveler for your warehouse, understanding the different types available is crucial for optimizing efficiency and safety. Hydraulic dock levelers typically fall into three main categories: edge-of-dock levelers, pit levelers, and portable levelers. According to a recent industry report by the Material Handling Institute, edge-of-dock levelers are ideal for low-traffic operations with minimal height variance, offering a cost-effective solution. They feature a simple mechanical design and operate directly from the loading dock's edge, making them straightforward to install and maintain.

On the other hand, pit levelers are designed for high-traffic environments and provide a versatile solution for varying load heights. These dock levelers are installed within a pit, allowing for seamless loading and unloading from trucks of different sizes. The Hydraulic Institute notes that pit levelers not only enhance safety but also reduce the risk of damages during loading operations. Their capacity typically ranges from 30,000 to 50,000 pounds, ensuring they can handle substantial loads efficiently. Lastly, portable levelers offer flexibility and can be moved to different locations as needed, making them suitable for operations with varying loading requirements. Each type has its own set of benefits, making it essential for warehouse managers to assess their specific operational needs before making a decision.

When selecting a hydraulic dock leveler for your warehouse, evaluating load capacity and compatibility with your operations is crucial. The load capacity of a dock leveler determines its ability to handle the weight of incoming and outgoing vehicles, pallets, and materials. It's essential to analyze the maximum weights you expect to transport regularly and choose a leveler with a rated load capacity that meets or exceeds these demands. Overloading a dock leveler can lead to operational inefficiencies and potential damage, so understanding your warehouse's specific needs is key to making an informed decision.

In addition to load capacity, compatibility with existing warehouse operations is vital. Consider the layout of your loading bay and the types of vehicles you will be using. The dock leveler's design should fit seamlessly with the height and width of your delivery trucks to ensure smooth transitions and reduce the risk of accidents. Additionally, factors such as the frequency of loading and unloading operations, as well as the types of materials being handled, will influence the choice of a hydraulic dock leveler. Ultimately, a thorough analysis of these factors will help you select a unit that enhances productivity and safety in your warehouse environment.

Maintaining hydraulic dock levelers is crucial for ensuring safe and efficient operations in any warehouse. Regular inspections should be conducted to identify any wear and tear on the components. This includes checking hydraulic fluid levels, inspecting seals for leaks, and ensuring that all electrical and mechanical systems are functioning properly. By addressing these maintenance tasks promptly, potential hazards can be minimized, reducing the risk of accidents during loading and unloading.

Safety is equally important when operating hydraulic dock levelers. Train staff on best practices, including proper loading techniques and the significance of using dock seals and shelters to prevent accidents and injuries. It is vital to establish protocols for the safe use of levelers, including never exceeding weight limits and ensuring that forklifts and pallets are correctly positioned. Implementing regular safety drills can also help reinforce these practices, creating a culture of safety within the warehouse environment.

| Feature | Description | Maintenance Tips | Safety Tips |

|---|---|---|---|

| Capacity | Select based on maximum load requirements. | Inspect hydraulic fluids regularly. | Always use safety barriers when operating. |

| Platform Size | Choose a size that accommodates your docks. | Check for wear and tear on the platform weekly. | Ensure operators are trained for usage. |

| Power Supply | Correlate with warehouse power availability. | Inspect electrical connections frequently. | Avoid using damaged extension cords. |

| Control System | Choose between manual or automatic options. | Test controls monthly for responsiveness. | Keep control areas clear of obstructions. |

| Durability | Consider materials that withstand wear. | Regularly clean to extend life span. | Implement lock-out/tag-out procedures. |