In the ever-evolving landscape of logistics and warehousing, choosing the right dock leveler for your loading dock needs is crucial for operational efficiency and safety. As we approach 2025, this decision is more important than ever, particularly with advancements in technology and design. According to industry expert John Smith, a leading consultant in loading dock systems, “Selecting the appropriate dock leveler is not just about functionality; it’s about ensuring a seamless flow of operations that can adapt to the changing demands of the market.”

One of the options steadily gaining traction among logistics professionals is the serco dock leveler. Designed for durability and efficiency, these levelers offer enhanced features that cater to the diverse needs of modern warehouses. With a variety of models available, businesses are finding it essential to assess their specific requirements, from load capacities to integration with existing dock setups, to ensure they make the best choice.

As we delve into the various factors to consider when selecting a dock leveler, it's imperative to focus on adaptability, safety standards, and maintenance requirements. With the insights provided by industry professionals and the innovative solutions offered by products like the serco dock leveler, you’ll be better equipped to enhance your loading dock operations in the years to come.

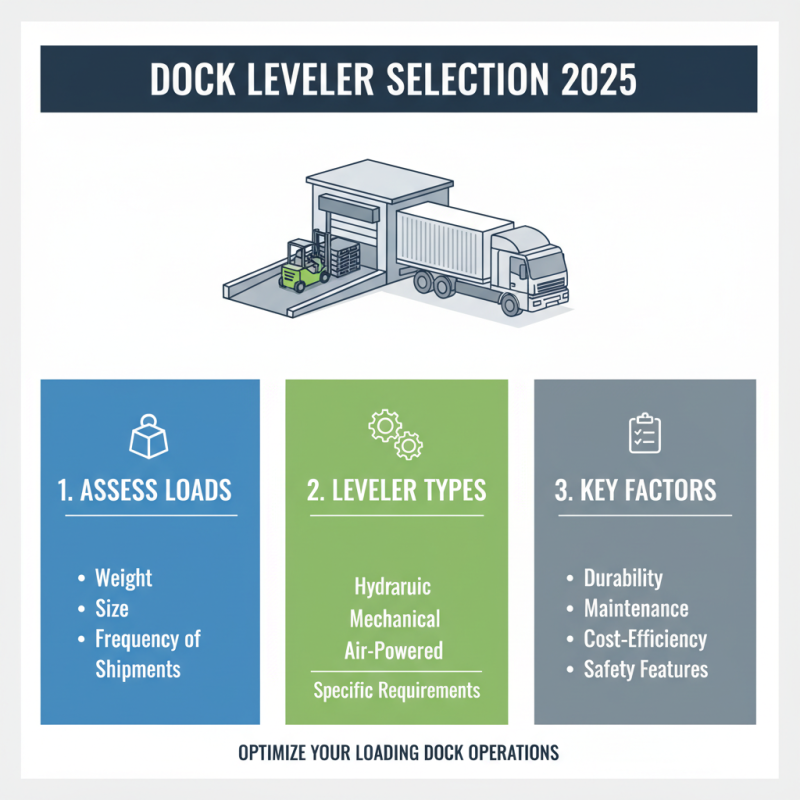

When selecting a dock leveler for your loading dock needs in 2025, understanding the various types available is crucial. The primary types of dock levelers include mechanical, hydraulic, and air-powered systems. Mechanical dock levelers are known for their simplicity and durability, making them ideal for facilities with minimal lifting requirements. Conversely, hydraulic dock levelers offer greater versatility and smoother operation, often preferred in high-traffic environments. Air-powered dock levelers, while relatively rare, provide quick deployment and are perfect for businesses that demand rapid loading and unloading.

Tips:

It's also essential to assess the installation space and the types of vehicles accessing the dock. Some levelers are designed for specific truck heights and can adjust to accommodate various vehicles, improving loading efficiency. Make sure to consider future needs, including potential expansions or changes in volume, which might affect your dock configuration.

When selecting the right dock leveler for your loading dock needs in 2025, several key factors should be taken into consideration. First, assess the types of loads you frequently handle. Consider the weight, size, and frequency of shipments, as these factors greatly influence your choice of leveler type. Whether it's a hydraulic, mechanical, or air-powered dock leveler, each option offers distinct advantages suited for specific loading requirements.

Another important aspect to evaluate is the dock's design and traffic patterns. Measure the height disparity between the loading dock and the trucks to determine the necessary leveler capacity and range. Taking into account the frequency of dock usage can also guide your decision; a model that can withstand high traffic will be essential for busy operations to ensure longevity and reliability.

**Tips:** Always consider the maintenance requirements of the dock leveler you choose. Regular maintenance checks can prevent unexpected downtime and costly repairs. Additionally, look for features like safety mechanisms, which can enhance dock operation efficiency and worker safety. Lastly, consult with your team to understand their preferences and needs, as their input can be invaluable in selecting a leveler that enhances operational efficiency.

When selecting the right dock leveler for your loading dock needs, evaluating the specific requirements of your operation is crucial. Different industries and warehouse environments have distinct standards regarding load capacities, dock heights, and preferred loading/unloading processes. Begin by assessing the types of vehicles that will access your loading dock, as this will influence the height and width specifications of the dock leveler. Additionally, consider the maximum weight of the cargo being moved and the frequency of loading activities, as these factors will determine the necessary durability and operational efficiency of the leveler.

Another essential consideration is the environmental conditions of your loading dock. If your dock faces exposure to harsh weather elements, you might need a leveler designed to withstand such conditions, including options for waterproof materials or enhanced sealing features. Furthermore, the floor type and surface grade of your loading dock should be evaluated, as these characteristics will affect how well different leveler designs perform. By systematically analyzing these specific requirements, you can ensure that you select a dock leveler that not only meets the demands of your daily operations but also enhances safety and efficiency in your loading processes.

| Dock Leveler Type | Load Capacity (lbs) | Platform Size (ft) | Operating Method | Ideal Usage |

|---|---|---|---|---|

| Hydraulic Leveler | 30,000 | 6 x 8 | Hydraulic | Heavy-Duty Warehousing |

| Mechanical Leveler | 20,000 | 6 x 7 | Mechanical | Medium-Duty Shipping |

| Pneumatic Leveler | 15,000 | 5 x 6 | Pneumatic | Light-Duty Retail |

| Edge-of-Dock Leveler | 10,000 | 4 x 5 | Manual | Light-Duty Applications |

When selecting the right dock leveler for your loading dock needs in 2025, it’s crucial to compare features and benefits to ensure optimal efficiency and safety. Modern dock levelers vary significantly in design and functionality, with options like hydraulic, mechanical, and air-powered systems. According to the Material Handling Industry (MHI) report published in 2023, hydraulic levelers are favored for their ease of use and ability to handle heavy loads, boasting a higher weight capacity of up to 35,000 pounds. In contrast, mechanical levelers provide cost savings and lower maintenance requirements, making them suitable for lighter loads or facilities with limited budgets.

From an operational perspective, the choice of a dock leveler can significantly impact workflow efficiency. A recent study indicated that facilities using automated dock levelers can reduce loading times by as much as 25%, leading to increased productivity and improved labor cost-effectiveness. Safety features are equally important; many modern dock levelers come equipped with advanced systems such as safety toe guards, non-skid surfaces, and integrated sensors that prevent accidents by ensuring a secure fit between the truck and the loading dock. Evaluating these features against your specific operational needs will guide you in making an informed decision tailored to your facility's demands.

When selecting a dock leveler, maintenance and safety considerations are paramount to ensure optimal performance and longevity. According to a report by the National Institute for Occupational Safety and Health (NIOSH), nearly 25% of loading dock incidents are attributable to equipment failure. Regular inspections and maintenance are essential to mitigate such risks. A well-maintained dock leveler reduces the chances of accidents and enhances operational efficiency. For instance, identifying wear and tear on hydraulic systems or seals can prevent costly breakdowns and prolonged downtimes.

Safety features should also be a priority when evaluating dock levelers. The latest safety standards, as set forth by the American National Standards Institute (ANSI), emphasize the importance of mechanisms that prevent accidental disengagement during loading and unloading. For example, dock levelers equipped with safety straps or toe guards can significantly reduce the risk of injuries to workers. Furthermore, implementing a maintenance schedule, as outlined in the International Loading Dock and Door Association (ILDDA) guidelines, can help ensure that each dock leveler is consistently evaluated for both functionality and safety compliance, fostering a safer working environment.