When it comes to enhancing the efficiency of your loading and unloading operations, proper dock leveler installation is crucial. It serves as the bridge between your warehouse floor and the delivery vehicles, ensuring smooth transitions that minimize both time and potential damage to goods. A well-installed dock leveler not only optimizes workflow but also contributes to workplace safety by reducing the risk of accidents caused by uneven surfaces.

The process of dock leveler installation involves careful planning and execution to achieve maximum results. From selecting the right type of leveler for your specific needs to ensuring precise measurements and alignment, every detail matters. Furthermore, the importance of regular maintenance cannot be overstated, as it directly impacts the longevity and performance of the equipment. By adhering to best practices during installation and operation, you can significantly enhance productivity and protect your investment.

In this article, we will provide you with ultimate tips for dock leveler installation that will help you maximize efficiency in your loading operations. By following these guidelines, you can ensure your facility runs smoothly, safely, and effectively, while fully leveraging the benefits of an optimal dock leveler setup.

Dock levelers play a crucial role in facilitating efficient warehouse operations, serving as the essential link between loading docks and trucks. According to a report by the Industrial Truck Association, efficient dock systems can improve loading and unloading times by up to 25%, significantly impacting overall productivity. This efficiency not only reduces operational costs but also enhances safety by minimizing the risk of accidents caused by uneven loading surfaces.

Furthermore, the importance of dock levelers extends beyond mere operational efficiency; they also contribute to inventory management. A study by the Warehousing Education and Research Council has shown that optimizing loading dock performance can lead to a 15% increase in inventory accuracy. Properly installed and maintained dock levelers ensure that goods can be quickly and securely transferred, minimizing the risk of damage during transit and enabling warehouses to maintain a leaner inventory. This efficiency is particularly vital in industries facing tight deadlines and customer expectations, underscoring the need for investing in high-quality dock leveler solutions as part of a comprehensive warehouse strategy.

| Tip | Importance | Best Practice |

|---|---|---|

| Check Load Capacity | Ensures safety and prevents equipment damage | Consult manufacturer specifications before installation |

| Inspect for Leveling | Improves efficiency in loading and unloading | Use a level tool to ensure proper alignment |

| Consider Environmental Conditions | Reduces wear and tear on the leveler | Choose materials suitable for outdoor use if needed |

| Use Proper Anchoring | Stabilizes the leveler and enhances safety | Follow installation guidelines for anchoring systems |

| Maintain Regular Inspections | Prevents unexpected breakdowns and injuries | Schedule inspections every 6 months |

When selecting a dock leveler, several key factors significantly influence its efficiency and overall performance. According to a report by the Material Handling Industry (MHI), nearly 60% of loading dock accidents are attributed to improper dock leveler installation and selection. Thus, understanding these factors is paramount for maximizing operational efficiency. Load capacity is one of the first considerations; ensuring that the leveler can support the weight of the materials being handled can prevent failures and downtime. Dock levelers designed for higher weight capacities can function effectively in high-demand environments, reducing the likelihood of breakage and maintenance costs.

Another vital aspect is the operating environment. For instance, climate and exposure to certain chemicals can affect the longevity and functionality of the leveler. According to research from the American Society of Safety Professionals (ASSP), selecting a dock leveler that can endure specific environmental conditions—such as extreme temperatures or exposure to corrosive substances—can enhance its lifespan by up to 30%. Moreover, the type of loading equipment and the frequency of use also play critical roles. High-frequency operations may benefit from hydraulic levelers, which provide smooth and efficient transitions, thus optimizing the loading and unloading process significantly. Addressing these key factors can lead to improved safety and productivity at the dock, ultimately contributing to a more efficient supply chain.

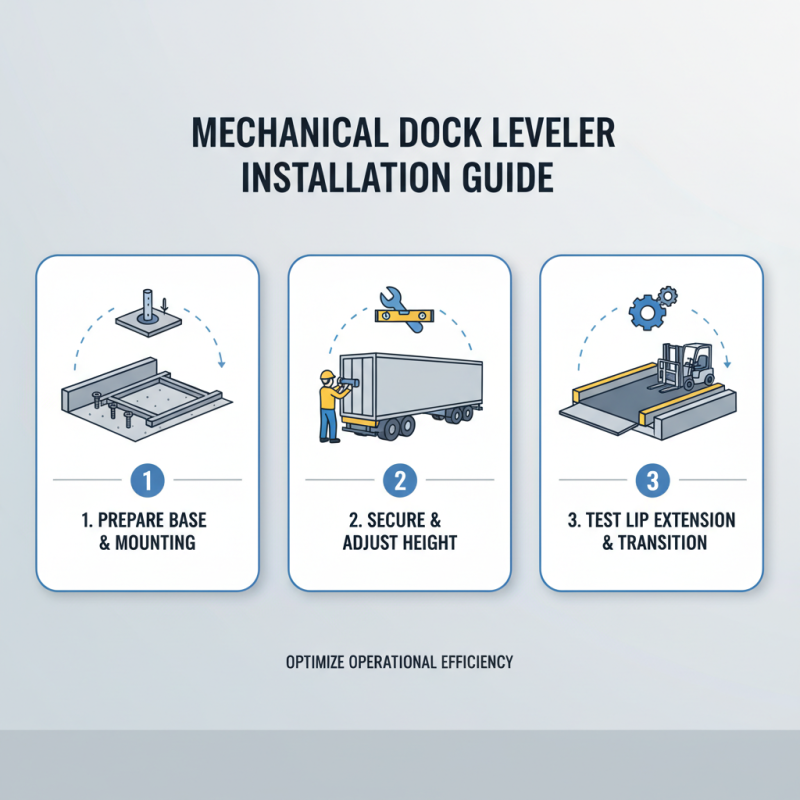

When installing dock levelers, understanding the different types available and the specific requirements for each can greatly enhance operational efficiency. Start with the most common type, the mechanical dock leveler. To install this, ensure you have a solid base and use the appropriate mounting hardware. Begin by securing the leveler in its intended position and adjusting it to match the height of the truck bed. Make sure to check that the lip extends properly for seamless transitions.

Next, consider hydraulic dock levelers, which offer a higher degree of flexibility. For these installations, ensure the hydraulic system is set up correctly. Begin by placing the unit in the dock pit, ensuring it is level and stabilized. Connect the hydraulic lines, and test the leveler to confirm that it rises and lowers smoothly. Regular maintenance checks after installation will ensure long-term efficiency and performance.

Finally, for air-powered dock levelers, proper air supply connections and settings are critical. Install the leveler according to the manufacturer’s guidelines, ensuring that the air bladder inflates fully for optimal operation. Once installed, check for any leaks in the air lines and verify that the unit operates at the correct pressure to facilitate safe and efficient loading and unloading operations. By following these steps for each type of dock leveler, you can ensure reliable installations that contribute to maximum efficiency in your loading dock operations.

When installing dock levelers, utilizing the right tools and adhering to safety precautions are paramount for ensuring efficiency and preventing workplace incidents. Essential tools for this task include a hydraulic lift, wrenches, and safety harnesses. A hydraulic lift can streamline the heavy lifting required during installation, while wrenches help with securing the leveler in place. According to the Occupational Safety and Health Administration (OSHA), approximately 20% of workplace injuries are caused by improper use of tools and equipment. Therefore, having the correct tools not only enhances efficiency but also promotes safety on-site.

Prioritizing safety precautions is equally important. Always wear personal protective equipment (PPE) such as gloves, hard hats, and steel-toed boots to safeguard against potential hazards. Additionally, ensure that all team members are familiar with the installation guidelines and emergency protocols. Research by the National Safety Council indicates that effective safety training can reduce workplace injuries by up to 30%. As a tip, designate a site manager to oversee the installation process, ensuring that everyone follows safety measures and operates equipment correctly.

Lastly, before commencing the installation, conduct a thorough inspection of the dock area and equipment to identify any potential hazards. Keeping the work area organized and free from debris can prevent accidents and improve efficiency. By committing to these essential tools and safety measures, you not only enhance the installation process but also foster a safer working environment for everyone involved.

Proper maintenance of dock levelers is essential for ensuring their longevity and optimal performance. Regular inspections and servicing can significantly mitigate the risk of failures, which can disrupt operations and lead to costly downtime. According to a report by the Material Handling Industry, improperly maintained dock equipment can lead to operational inefficiencies that may cost businesses up to 20% more in expenses annually. To avoid these pitfalls, operators should develop a routine maintenance schedule that includes checking for wear and tear, lubricating moving parts, and ensuring that all safety features are functioning correctly.

Tips for effective maintenance include training staff on the importance of proper usage to avoid excessive strain on the levelers. Operators should also keep a log of all maintenance activities. This not only assists in tracking the condition of the equipment but can also be beneficial when reviewing any issues that arise. Furthermore, using high-quality components during repairs and replacements can significantly improve durability and performance. The National Association of Wholesaler-Distributors highlights that investing in quality maintenance can reduce repair costs by as much as 15% over time, ultimately leading to greater operational efficiency.

In addition to regular maintenance, keeping the area around dock levelers clean and free of debris is crucial. A cluttered workspace can lead to accidents and hinder the levelers' operational capabilities. Regular cleaning and organization can help prolong the life of the equipment. By adhering to these practices, facilities can ensure their dock levelers remain efficient and reliable, contributing to smoother logistics and improved productivity.