When it comes to improving operational efficiency in warehouses and loading docks, the importance of choosing the right dock plates cannot be overstated. Dock plates play a crucial role in facilitating smooth transitions between vehicles and loading areas, ensuring safe and efficient material handling. Selecting the appropriate dock plates not only enhances productivity but also minimizes the risk of accidents during the loading and unloading process.

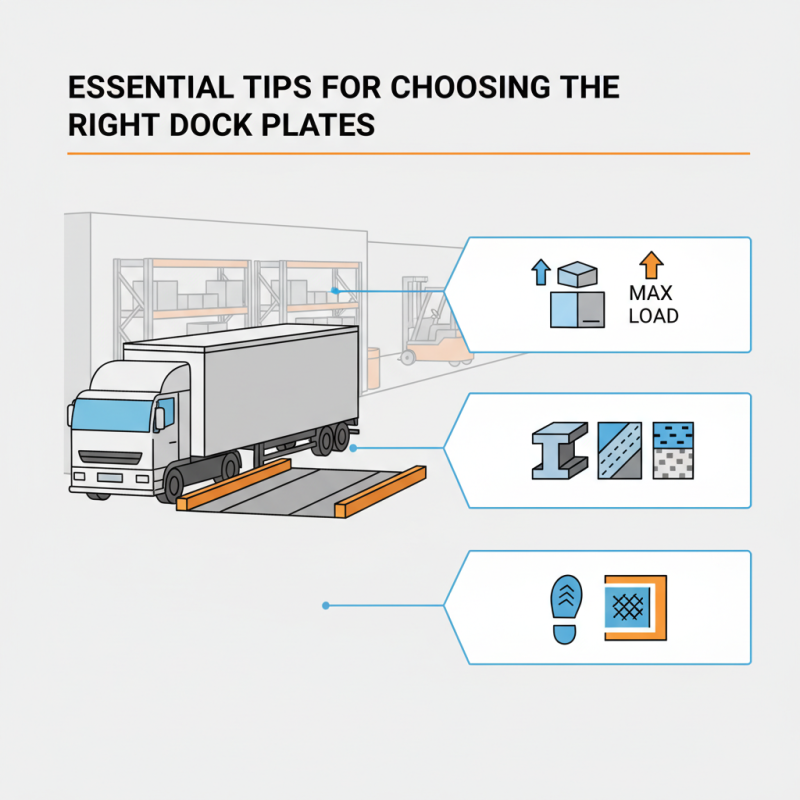

Understanding the various types of dock plates available, along with their specific features and benefits, is essential for making an informed decision. Factors such as weight capacity, material, and size should be considered to accommodate the unique needs of your operations. Additionally, attention to safety features, such as non-slip surfaces and reinforced edges, can significantly reduce workplace hazards and promote a safer working environment.

In this guide, we will explore essential tips for selecting the right dock plates tailored to your operational requirements, helping you to optimize your loading dock processes. Whether you're managing a small warehouse or a large distribution center, the right dock plates can make a significant difference in your overall efficiency and safety.

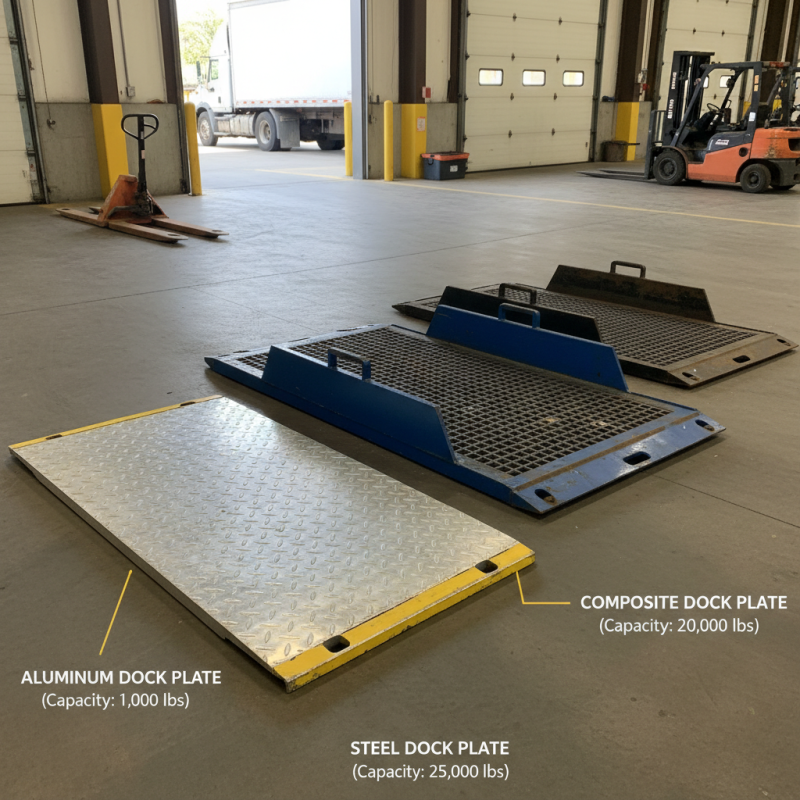

When selecting dock plates, it’s essential to understand the variety of types available to meet specific operational needs. Each type of dock plate serves a unique purpose based on the nature of the loads being handled. For instance, aluminum dock plates are lightweight yet durable, making them ideal for light to medium loads, while steel dock plates offer superior strength for heavier materials. The choice between these materials can significantly impact the efficiency and safety of loading and unloading processes.

Another critical factor to consider is the design of the dock plate. Some plates feature beveled edges for smoother transitions, reducing the risk of accidents and streamlining movement. Additionally, non-slip surfaces are crucial for maintaining traction, especially in environments prone to moisture or spills. Furthermore, the capacity rating of the dock plate must align with the maximum load expected during operations. Choosing the right type not only enhances safety but can also improve overall productivity, ensuring that goods move quickly and efficiently between trucks and warehouses.

| Dock Plate Type | Material | Weight Capacity (lbs) | Size (inches) | Best Use Case |

|---|---|---|---|---|

| Aluminum Dock Plate | Aluminum | 1,500 | 60 x 36 | Light loads, frequent use |

| Steel Dock Plate | Steel | 2,500 | 72 x 48 | Medium to heavy loads |

| Rubber Dock Plate | Rubber | 1,000 | 48 x 30 | Gentle surface, minimizing damage |

| Heavy-Duty Dock Plate | Steel | 5,000 | 84 x 36 | Heavy industrial use |

| Portable Dock Plate | Aluminum | 1,200 | 60 x 32 | Temporary loading and unloading |

When selecting dock plates for your facility, several key factors must be taken into account to ensure optimal operation and safety. First and foremost, consider the weight capacity of the dock plates. Assess the maximum load that will be transported over the plates, as choosing a plate that cannot handle your requirements can lead to accidents or equipment damage. It's also crucial to examine the material of the dock plates; options such as aluminum or steel can offer striking balance between durability and weight.

Another essential factor is the size and configuration of the dock plates. The dimensions should align with the height of your loading dock and the vehicles that will be using the plates. A proper fit will minimize the risk of spills and accidents during loading and unloading. Additionally, the surface texture is important; opting for non-slip surfaces can significantly enhance safety and reduce the risk of slipping, especially in environments where moisture is present.

When selecting dock plates, it's beneficial to consider how often they will be used. Frequent use may warrant investing in more robust, heavy-duty dock plates that can withstand daily wear and tear. Finally, don't forget about the ease of maneuverability; the design should facilitate smooth transitions to prevent strain on workers. By carefully evaluating these aspects, you can enhance your operational efficiency and safety in the loading and unloading processes.

When selecting dock plates, prioritizing safety features is crucial to minimizing risks in loading and unloading operations. According to industry data from the Material Handling Industry of America (MHIA), approximately 25% of workplace injuries occur during material handling processes. Therefore, choosing dock plates with robust safety attributes can significantly reduce these incidents. Look for features such as non-slip surfaces, which provide better traction and prevent accidents due to slips and falls. Additionally, many modern dock plates come equipped with safety lock mechanisms that secure the plate in place during use, ensuring stability and reducing the chance of accidents.

Moreover, visibility is another essential aspect to consider. Dock plates with reflective or brightly colored markings can enhance visibility, especially in low-light conditions. According to OSHA, improved visibility in hazardous areas can lead to a 40% reduction in accident rates. Additionally, a weight rating appropriate for the loads being transferred is vital; most dock plate injuries occur due to overloading. A comprehensive assessment of the load capacity, combined with safety features, can help create a safer workplace environment, ultimately enhancing operational efficiency while protecting employees.

When selecting the right dock plates for enhanced operational efficiency, the material choice plays a crucial role in determining their performance, durability, and overall suitability for specific tasks. The two most commonly used materials for dock plates are aluminum and steel, each presenting unique advantages and disadvantages. According to a report by the Material Handling Industry (MHI), aluminum dock plates are approximately 30% lighter than their steel counterparts, making them easier to handle and reposition for various loading tasks. They also resist corrosion, which is particularly beneficial in environments exposed to moisture.

On the other hand, steel dock plates offer a higher tensile strength, making them ideal for heavier loads, often exceeding capacities of 2,500 pounds. The American Society of Civil Engineers (ASCE) highlights that steel's durability contributes to a longer lifespan in high-impact settings, such as warehouses that handle heavy machinery or bulky goods. However, steel plates are more prone to rusting when not properly treated or maintained, which may lead to increased replacement costs over time. Ultimately, the decision between aluminum and steel should consider not only the specific load requirements but also how each material's characteristics align with the operational environment and long-term cost implications.

Proper maintenance practices are crucial for extending the life of dock plates, ensuring that they remain functional and efficient for daily operations. Regular inspections should be conducted to identify any signs of wear, such as cracks, bends, or surface degradation. These inspections should encompass all aspects of the dock plate, including its structural integrity and the condition of the support frames. By addressing minor issues before they escalate, operations can reduce the risk of equipment failure and maintain optimal performance.

Additionally, maintaining a clean environment around the dock plate is essential. Debris, oil, and other contaminants can lead to slippery surfaces, increasing the risk of accidents. Establishing a routine cleaning schedule can help keep the area clear and safe. Furthermore, lubrication of moving parts and hinges can minimize friction, allowing for easier handling and extending the overall lifespan of the dock plate. Incorporating these simple yet effective maintenance practices will not only enhance the operational efficiency of the dock plates but also ensure a safer working environment for employees.