In the fast-paced world of logistics, the safety of loading docks is paramount. Industry expert John Thompson, a leading consultant in dock safety solutions, emphasizes the importance of loading dock bumpers: “The right bumpers are not just a protective measure; they are a critical component in preventing accidents and ensuring the longevity of both dock structures and vehicles.” This statement highlights the essential role these protective fixtures play in safeguarding against the potential damages caused by the repetitive impact of trucks maneuvering in and out of loading areas.

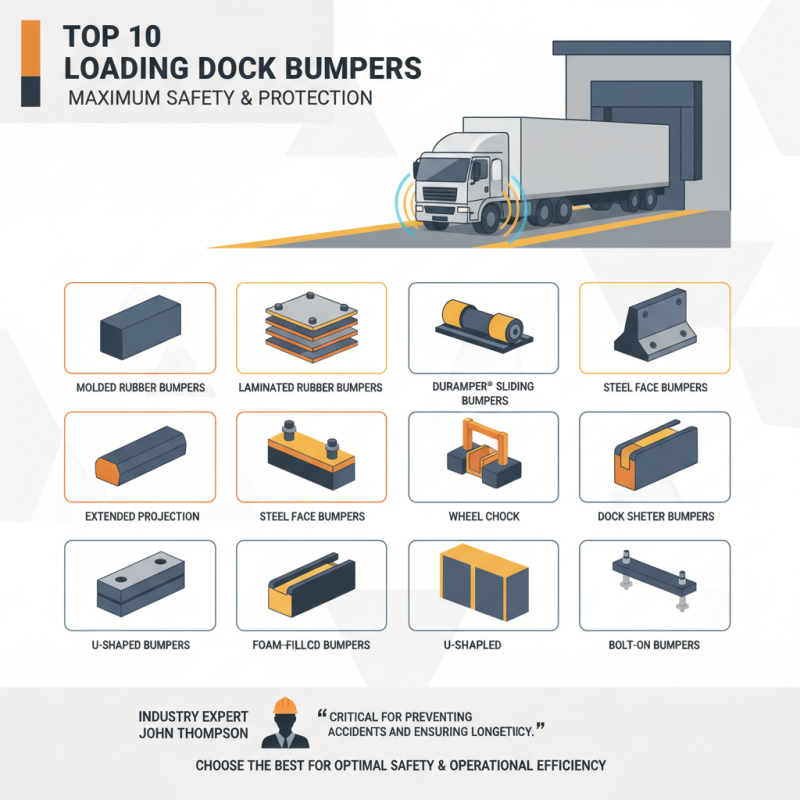

Loading dock bumpers are designed to absorb shock and minimize the risk of damage during loading and unloading processes. As warehouses and distribution centers continue to evolve, the demand for effective safety solutions becomes increasingly vital. With various designs and materials available, selecting the right bumpers can significantly enhance operational efficiency and safeguard personnel. The top 10 loading dock bumpers featured in this guide will help facility managers choose the best options for optimal safety and protection, ensuring their operations run smoothly and without incidents. In this critical evaluation, we will analyze the features, benefits, and applications of the most effective loading dock bumpers available today.

When selecting loading dock bumpers, several key features should be considered to ensure maximum safety and protection for facilities and personnel. One of the most critical factors is the material used in the bumper construction. High-quality rubber or polyurethane materials provide superior shock absorption and resilience against impact, effectively safeguarding both vehicles and the dock structure. According to industry reports, improper bumper choice can lead to increased maintenance costs by up to 25%, emphasizing the importance of selecting the right material for durability and performance.

Another important aspect is the bumper size and design. Bumpers come in various lengths and widths, with options tailored to fit different dock configurations and vehicle types. A report from a leading logistics research firm indicated that docks equipped with appropriately sized bumpers experienced a 30% reduction in damage incidents. Proper consideration of these dimensions will help prevent both vehicle and structural damage, enhancing operational efficiency and worker safety.

Tips for choosing loading dock bumpers include evaluating their ease of installation and maintenance. Bumpers that are easy to install and maintain can minimize downtime during setup and ensure that facilities remain operational. Additionally, consider the environmental conditions where the bumpers will be used; for instance, bumpers that resist UV degradation or temperature fluctuations may provide longer-lasting protection. Making informed choices based on these features can lead to safer and more efficient loading operations.

Loading dock bumpers are essential safety features designed to protect both vehicles and the loading dock structure during cargo loading and unloading operations. They come in various types, each tailored to specific needs and environments. One common type is the rubber bumper, known for its durability and shock-absorbing properties. These bumpers are effective in minimizing impact damage from trucks, ensuring that both the dock and vehicles remain intact.

Another popular option is the steel bumper, which is ideal for high-traffic areas where heavy-duty protection is required. Steel bumpers are robust and can withstand repeated impacts, making them suitable for industrial settings. Additionally, there are molded bumpers, which provide a more customized fit for different loading dock configurations. These bumpers are often designed to contour to the loading dock's shape, offering enhanced protection and stability during loading processes. By understanding the different types of loading dock bumpers available, businesses can make informed decisions to enhance safety and efficiency in their operations.

When evaluating the best loading dock bumpers for safety and protection, it's essential to consider various factors such as material durability, design effectiveness, and installation ease. The market offers a diverse range of options, and understanding the features of each can significantly enhance operational safety. Look for bumpers made from high-quality rubber or polyurethane, as these materials provide robust shock absorption and weather resistance. Additionally, various designs, including flexible and rigid profiles, can cater to specific loading dock configurations and daily operations.

Tips for selecting the right loading dock bumpers include assessing your facility's unique needs before making a purchase. Consider the volume of traffic your dock experiences and the types of vehicles that frequent the area. For high-impact applications, investing in heavier-duty bumpers can offer better long-term performance and protection. Another crucial aspect is installation; some bumpers come with user-friendly mounting systems, which can save time and costs during setup.

Moreover, regularly inspecting the condition of your dock bumpers is vital for ongoing safety. Look for signs of wear and tear, as replacing damaged bumpers promptly can prevent more significant issues down the line. Keeping the loading area clean and free of obstacles can also extend the lifespan of your bumpers while ensuring a safer working environment for personnel and equipment alike.

When it comes to ensuring the safety and efficiency of loading docks, proper installation and maintenance of bumpers are crucial. Loading dock bumpers act as a protective barrier between vehicles and the dock structure, helping to minimize damage during the loading and unloading process. For successful installation, ensure that the bumpers are mounted securely to the dock face at the right height. It's important to align the bumpers with the typical height of the trucks that will be servicing the dock, providing optimal protection against impact.

Regular maintenance of loading dock bumpers is essential to extend their lifespan and maintain safety standards. Inspect the bumpers for signs of wear or damage at least once a month. Check for cracks, soft spots, and other degradation that could affect their performance. If any issues are identified, replace the bumpers promptly to avoid risking damage to the dock or injury to personnel. Additionally, consider applying a protective sealant to the bumpers if they are made from materials exposed to harsh weather conditions, helping to enhance their durability.

For best practices, always ensure that the loading dock area is well-lit and free from obstructions that could impede visibility. Training staff on the proper use of the loading dock and the importance of the bumpers can further enhance safety. Regularly reviewing safety protocols and conducting drills can instill a culture of safety at the loading dock, keeping employees and equipment secure while optimizing operations.

Loading dock bumpers are essential components designed to enhance safety and protection in loading and unloading areas. Understanding the safety standards and regulations surrounding their use can help ensure compliance and reduce risks during dock operations. The Occupational Safety and Health Administration (OSHA) provides guidelines indicating that adequate bumpers are crucial for preventing damage to vehicles and structures. This includes maintaining proper installation and ensuring they are made from durable materials that can withstand repeated impacts.

When selecting loading dock bumpers, it's vital to consider factors such as the weight and type of vehicles that will frequently be interacting with the dock. Additionally, organizations should regularly inspect bumpers for wear and tear to ensure they remain effective in protecting both the dock and the vehicles.

Tips: Ensure that bumpers are installed at the correct height to accommodate the various types of trailers that will be used. Also, consider incorporating reflective markings on bumpers to increase visibility, especially in low-light conditions. It's advisable to provide training for employees on the importance of loading dock safety practices and how to effectively utilize bumpers to minimize risks during operations.