In today's fast-paced logistics environment, the importance of safety and efficiency in loading operations cannot be overstated. A crucial component that plays a significant role in achieving these objectives is the loading dock plate. According to industry expert John Smith, "Utilizing a loading dock plate not only enhances the safety of your loading operations but also streamlines the entire process, making it more efficient and cost-effective."

The loading dock plate serves as a vital link between a trailer and the loading dock, allowing for a smooth transition of goods while minimizing the risk of accidents. Properly equipped loading operations can significantly reduce the chances of slips, trips, and falls, which are common hazards in warehouses and distribution centers. Furthermore, a well-chosen loading dock plate can accommodate various heights and load capacities, ensuring that your operations are versatile and adaptable.

As organizations continue to strive for improved operational efficiency, investing in high-quality loading dock plates should be a top priority. By focusing on safety and functionality, businesses can not only protect their workforce but also enhance their productivity and service quality. The essential role of the loading dock plate in modern logistics underscores the need for businesses to prioritize this often-overlooked piece of equipment.

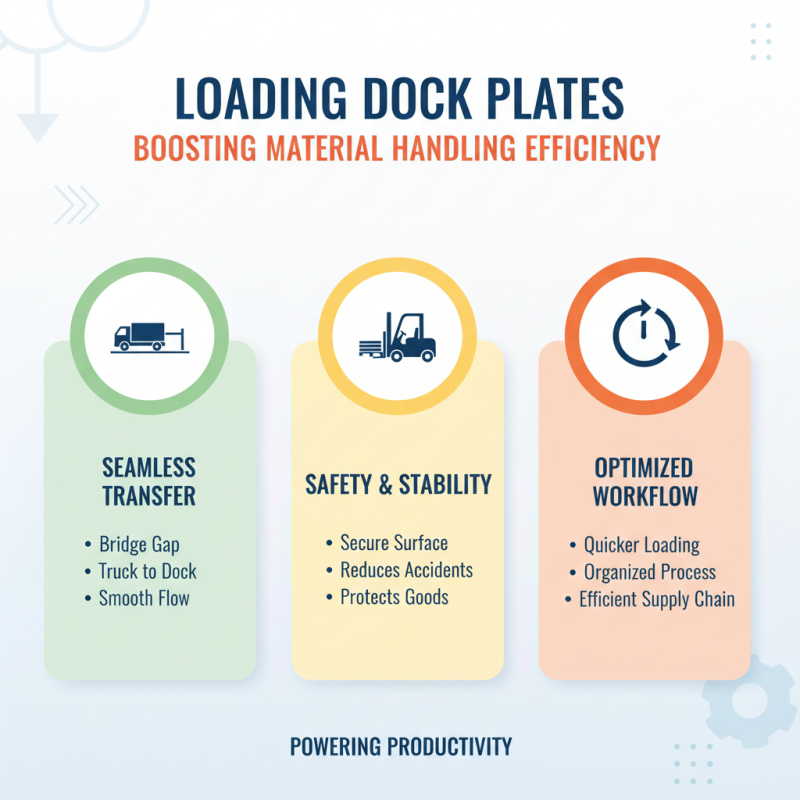

Loading dock plates play a crucial role in enhancing material handling efficiency during loading and unloading operations. These essential tools bridge the gap between trucks and loading docks, facilitating the smooth transfer of goods. By providing a stable and secure surface for pallet jacks, forklifts, and other material handling equipment, loading dock plates significantly reduce the risk of accidents and product damage. When properly utilized, they streamline workflows by allowing for quicker and more organized loading processes, ultimately contributing to a more efficient supply chain.

Moreover, the use of loading dock plates enhances safety by minimizing potential hazards associated with uneven surfaces. Without these plates, there is a greater chance of slips, trips, and falls, which can lead to workplace injuries. Loading dock plates are designed to accommodate various load capacities and can be easily adjusted to fit different heights, making them adaptable to a wide range of vehicles and freight types. Their presence not only promotes a safer working environment but also increases productivity, allowing businesses to handle more shipments in less time. This synergy between safety and efficiency underscores the importance of incorporating loading dock plates into any material handling operation.

When it comes to loading dock operations, safety standards play a crucial role in ensuring smooth and secure processes. According to the Occupational Safety and Health Administration (OSHA), improper loading and unloading can result in accidents leading to severe injuries or fatalities, underscoring the need for compliance with rigorous safety regulations. A loading dock plate, designed to bridge the gap between a truck and the loading dock, is essential in minimizing risks associated with height differences and unstable loads.

The American National Standards Institute (ANSI) outlines specific guidelines for loading dock equipment, emphasizing the necessity of having reliable load-bearing capabilities. Research indicates that about 25% of all workplace injuries occur during loading and unloading activities, primarily due to inadequate equipment or failure to follow safety protocols. By integrating high-quality loading dock plates that meet ANSI standards, facilities can significantly reduce the likelihood of such incidents. Moreover, regular training for staff on the proper use of dock equipment and adherence to safety guidelines can further enhance the operational safety and efficiency of loading operations.

Proper loading dock equipment, such as loading dock plates, plays a crucial role in enhancing safety and efficiency during loading operations. According to data from the National Institute for Occupational Safety and Health (NIOSH), workplace injuries related to loading and unloading activities account for a significant percentage of all workplace accidents. Specifically, studies show that effective use of loading dock plates can reduce the risk of injuries by up to 30%. This reduction is primarily due to the seamless transition they provide between different loading surfaces, minimizing trips, slips, and falls, which are prevalent causes of workplace injuries.

Moreover, the Bureau of Labor Statistics reports that safe loading and unloading practices can decrease the incidence of back injuries—one of the most common injuries among warehouse and dock workers—by around 40%. The implementation of loading dock plates not only aids in aligning vehicle beds with dock floors but also facilitates safe loading practices by providing a stable surface. This preventative measure is crucial, considering that injury-related costs can significantly impact a company's bottom line, with estimates indicating that a single workplace injury can cost an employer over $40,000 in medical expenses and lost productivity. Thus, investing in proper loading dock equipment is essential for safeguarding employees and improving operational efficiency.

| Year | Incidents Without Loading Dock Plates | Incidents With Loading Dock Plates | Injury Reduction (%) | Estimated Cost Savings ($) |

|---|---|---|---|---|

| 2019 | 150 | 50 | 66.67% | $200,000 |

| 2020 | 130 | 40 | 69.23% | $180,000 |

| 2021 | 100 | 30 | 70.00% | $150,000 |

| 2022 | 80 | 20 | 75.00% | $120,000 |

| 2023 | 50 | 10 | 80.00% | $100,000 |

When it comes to optimizing loading operations, choosing the right equipment is crucial.

Loading dock plates have emerged as a preferred solution due to their robustness and reliability, especially when compared to other loading aids.

Unlike ramps or temporary loading mats, dock plates provide a solid, level surface that minimizes the risk of accidents during loading and unloading.

They accommodate various vehicle heights and types, ensuring seamless transfers between truck and dock, which is essential for maintaining workflow efficiency.

Tips: Always ensure that your loading dock plate is rated for the specific weight and type of cargo you will be handling.

Regular maintenance checks are also advised to keep the plate in optimal condition and avoid any operational hazards.

While dock plates offer significant advantages, it’s important to consider alternatives such as dock levelers or inflatable dock seals.

Dock levelers automatically adjust to the height of the truck bed, which can be beneficial in high-volume environments.

Inflatable dock seals, on the other hand, help in maintaining temperature control in refrigerated loading applications.

Each solution has its unique benefits and potential drawbacks, making it essential to assess the specific needs of your operation before making a decision.

Tips: Conduct a thorough assessment of your loading and unloading environment.

Identify peak loading times and typical cargo types to determine which solution will enhance safety and efficiency best.

To ensure the longevity of loading dock plates, regular maintenance is essential. First and foremost, it's crucial to inspect the plates frequently for signs of wear, damage, or misalignment. Any noticeable cracks, corrosion, or warping should be addressed immediately to prevent accidents and prolong the lifespan of the equipment. Implementing a monthly check can help identify potential issues before they escalate, allowing for timely repairs or replacements without interrupting loading operations.

Additionally, cleaning the loading dock plates is vital for maintaining their integrity and performance. Debris, dirt, and spills can create hazardous surfaces and lead to premature wear. Utilize appropriate cleaning solutions and methods to remove any accumulated grime, ensuring that the plates remain in optimal condition. Furthermore, lubricating the hinges and moving parts periodically can aid in smooth operation, reducing friction and wear over time. By following these maintenance tips, loading dock plates can provide safe and efficient service, ultimately enhancing loading operations and minimizing downtime.