When it comes to efficient loading and unloading, dock levelers play a crucial role. According to industry expert Sarah Johnson, a leading voice in dock equipment, “Selecting the right dock levelers for sale can drastically improve warehouse efficiency.” This insight highlights the importance of choosing the right equipment.

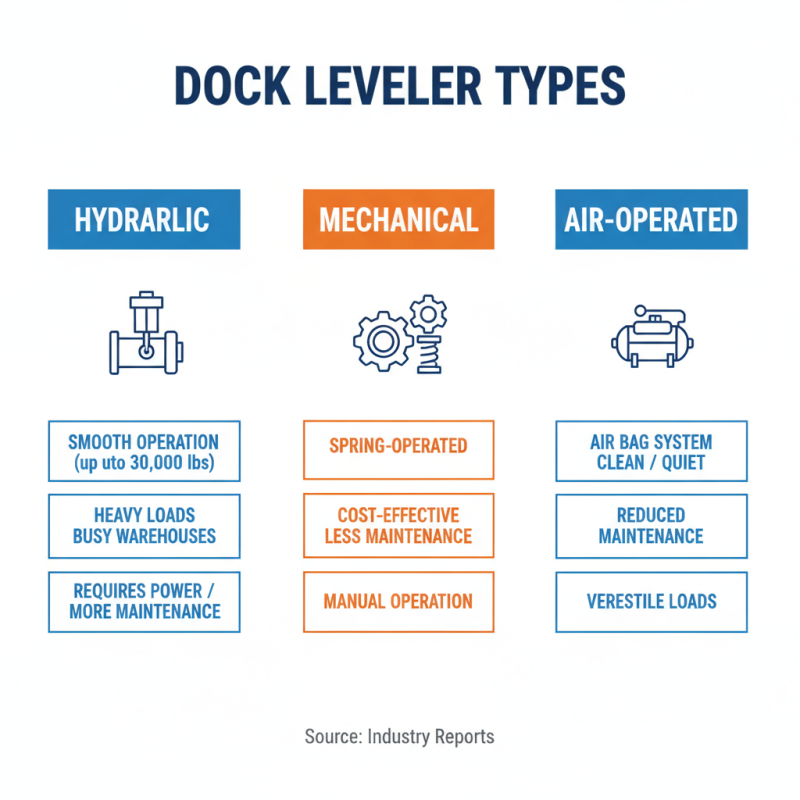

Dock levelers for sale come in various types, including hydraulic, mechanical, and manual options. Each type has its own advantages and disadvantages. For example, hydraulic dock levelers offer ease of use but may require more maintenance. On the other hand, mechanical options are often more durable but require more physical effort to operate. This variety creates confusion when making a decision.

Many companies overlook these differences and rush into purchasing. It’s vital to reflect on operational needs before making a choice. Investing time in understanding the features can lead to better long-term performance. It’s essential to weigh the pros and cons, as an ill-informed decision can lead to inefficiencies.

When selecting a dock leveler, understanding key features is essential. Safety is paramount. A good dock leveler should have safety features like edge-of-dock barriers and non-skid surfaces. These features reduce the risk of slips and falls. According to a 2022 industry report, workplaces that implement safety features see a 30% decrease in workplace accidents.

Another important aspect is the load capacity. Dock levelers need to handle heavy loads efficiently. Choose one that can support at least the maximum weight your operations require. Data indicates that over 70% of dock-related injuries occur when load capacities are exceeded. Investing in the right capacity protects both employees and equipment.

Consider the material and durability as well. Steel levelers are robust but may require more maintenance. Aluminum options are lighter, yet they may not endure heavy-duty tasks. A 2023 survey showed that 65% of facilities reported frequent repairs on inadequate levelers. This indicates the significance of choosing the right material to minimize long-term costs. Each choice carries potential challenges that deserve careful thought.

| Model | Weight Capacity | Platform Size | Material | Key Features |

|---|---|---|---|---|

| Model A | 30,000 lbs | 6' x 8' | Steel | Hydraulic operation, safety legs, automatic return |

| Model B | 25,000 lbs | 5' x 7' | Aluminum | Lightweight, corrosion-resistant, easy to operate |

| Model C | 40,000 lbs | 7' x 10' | Steel | Heavy-duty, adjustable height, anti-slip surface |

| Model D | 35,000 lbs | 6.5' x 9' | Composite | Weather-resistant, low maintenance, ergonomic design |

| Model E | 28,000 lbs | 5.5' x 7.5' | Steel | Foldable, space-saving, easy storage |

When considering dock levelers, various types cater to different operational needs. Hydraulic, mechanical, and air-operated levelers are the primary categories. Hydraulic dock levelers offer smooth operation and can handle heavy loads efficiently. Reports indicate that they have a load capacity of up to 30,000 lbs. This makes them ideal for busy warehouses. However, they require a power source, leading to higher maintenance costs.

Mechanical dock levelers are simpler. They use a spring mechanism and are less expensive. They might struggle with heavier loads compared to hydraulic models. Industry data shows they can handle loads up to 20,000 lbs. These levelers are popular due to their reliability and ease of use. Yet, they often lack the convenience of automated adjustments.

Air-operated levelers provide flexibility for various truck heights. Their inflatable pads help absorb impact, reducing wear and tear. However, these can be prone to leaks, requiring regular checks. Despite their benefits, such as easy adjustments, users often question their long-term durability. Each type presents unique advantages and challenges, making it essential to analyze specific operational requirements before making a purchase.

Investing in high-quality dock levelers brings numerous advantages. These devices are crucial for smooth loading and unloading operations. A reliable dock leveler ensures goods move efficiently between trucks and warehouses. Without them, delays and accidents may occur. Poor-quality equipment often leads to repair costs and downtime. A solid dock leveler improves productivity, which is vital for any business.

High-quality dock levelers are designed with durable materials. They can handle heavy loads without bending or breaking. This reliability means less maintenance is needed over time. Choosing the right leveler can reduce operational risks. Injuries on the job site can happen with faulty equipment. Prioritizing safety protects employees and the business’s reputation.

Moreover, investing in premium dock levelers can save money long-term. Lower initial costs often come with hidden expenses. Frequent repairs can rapidly increase overall costs. High-quality options may seem pricier at first, but they offer better value. Durability leads to fewer replacements and lower operational risks. Users must evaluate their choices carefully to ensure they invest wisely.

When selecting the right dock leveler, several factors come into play. A recent industry report highlights that about 70% of operational issues stem from improperly utilized equipment. This makes choosing quality dock levelers crucial for efficiency. Currently, the market offers several options, but some truly stand out.

One type of dock leveler features mechanical operation. These are simple, yet reliable. They typically require no electricity and are easier to maintain. Studies show that mechanical levelers often last longer than their powered counterparts. However, they can be physically demanding for workers, raising concerns about ergonomic safety.

Another recommended type is the air-powered dock leveler. They provide a smoother transition between the truck and dock. Surveys reveal that companies using air-powered levelers report a decrease in loading times by up to 30%. Yet, they may be prone to air system failures, which could lead to unplanned downtime. Choosing dock levelers involves thoughtful consideration of both efficiency and safety. Each option comes with strengths and weaknesses, demanding careful evaluation.

When choosing dock levelers, customer feedback plays a significant role. Users often highlight the importance of durability and ease of use. Many express their satisfaction with products that withstand heavy loads and frequent usage. Reviews frequently mention how specific models reduced downtime and improved workflow efficiency. However, some customers share concerns about installation challenges and maintenance requirements.

Tips for selecting a dock leveler: Always consider the weight capacity your operations demand. Do not overlook the installation process—it can be more complex than expected. Pay attention to any recurring issues mentioned in reviews. Some users faced difficulties with sealing and adjustments, which they found frustrating.

Many customers appreciate levelers that offer good traction. Feedback indicates that stable surface texture reduces accidents, especially during busy shifts. Yet, users occasionally reflect on the need for better customization options. Few levelers cater to unique shipping environments, which leaves some feeling dissatisfied with their choice. A thoughtful review of options can prevent future regrets.