In the fast-paced world of logistics and warehousing, the efficiency of your loading operations directly impacts your business’s bottom line. Choosing the right loading dock ramp can significantly enhance the productivity of your workforce, streamline the loading and unloading process, and improve safety standards. According to industry expert John H. Smith, a seasoned loading dock solutions consultant, “Selecting the appropriate loading dock ramp is not just about convenience; it's about creating a seamless workflow that optimizes every inch of your operation.”

With numerous options available, from portable ramps to fixed options, understanding your specific needs is essential. Whether you operate a small distribution center or a large-scale manufacturing facility, the right loading dock ramp can facilitate the transportation of goods, reduce delays, and minimize the risk of accidents. This guide will explore the critical factors you need to consider when selecting a loading dock ramp, ensuring that your investment contributes positively to your operational efficiency and safety protocols.

When selecting a loading dock ramp for your business, understanding the various types available is crucial for optimizing efficiency and safety. The primary categories include portable ramps, fixed dock ramps, and adjustable ramps. Portable ramps are designed for flexibility and can be easily moved as needed, making them ideal for businesses with fluctuating loading requirements. According to the 2022 Material Handling Industry Report, the demand for portable ramps has increased by 15% as businesses look to enhance versatility at loading sites.

Fixed dock ramps, on the other hand, provide a stable and permanent solution, commonly used in warehouses with consistent loading operations. These ramps are typically engineered to support heavy loads, with a weight capacity often exceeding 20,000 pounds. Adjustable ramps offer an innovative solution for accommodating different vehicle heights, and their market is projected to grow by 10% annually as more companies recognize the importance of adaptability in their operations. In fact, a study by Freight Transportation Research indicates that businesses investing in the right ramp solutions can increase productivity by up to 25%, highlighting the importance of choosing the right type for your specific needs.

| Ramp Type | Load Capacity (lbs) | Material | Typical Use | Installation Type |

|---|---|---|---|---|

| Portable Ramp | 1,500 | Aluminum | Lightweight loads | None required |

| Fixed Ramp | 3,000 | Steel | Heavy-duty loads | Permanent installation |

| Hydraulic Ramp | 6,000 | Steel/Aluminum | Frequent loading/unloading | Electric installation |

| Folding Ramp | 1,000 | Aluminum | Personal use / delivery | None required |

| Channel Ramp | 2,500 | Steel | Forklift access | Permanent installation |

When selecting a loading dock ramp for your business, several key factors should be carefully considered to ensure optimal functionality and safety. First, assess the weight capacity required for your operations. Loading dock ramps come in various materials and designs that support different weight limits, so it is crucial to choose one that can handle the heaviest equipment and materials you intend to move.

Another important factor is the ramp's incline angle. The optimal incline balances safety and efficiency, allowing smooth loading and unloading without risking injury or damage to the equipment. Be mindful of the height differences between the dock and the trailer, as this will determine the length of the ramp needed. Additionally, consider the surface texture of the ramp; a non-slip surface is essential to prevent accidents in wet or slippery conditions, thereby enhancing the overall safety level for your employees during operations.

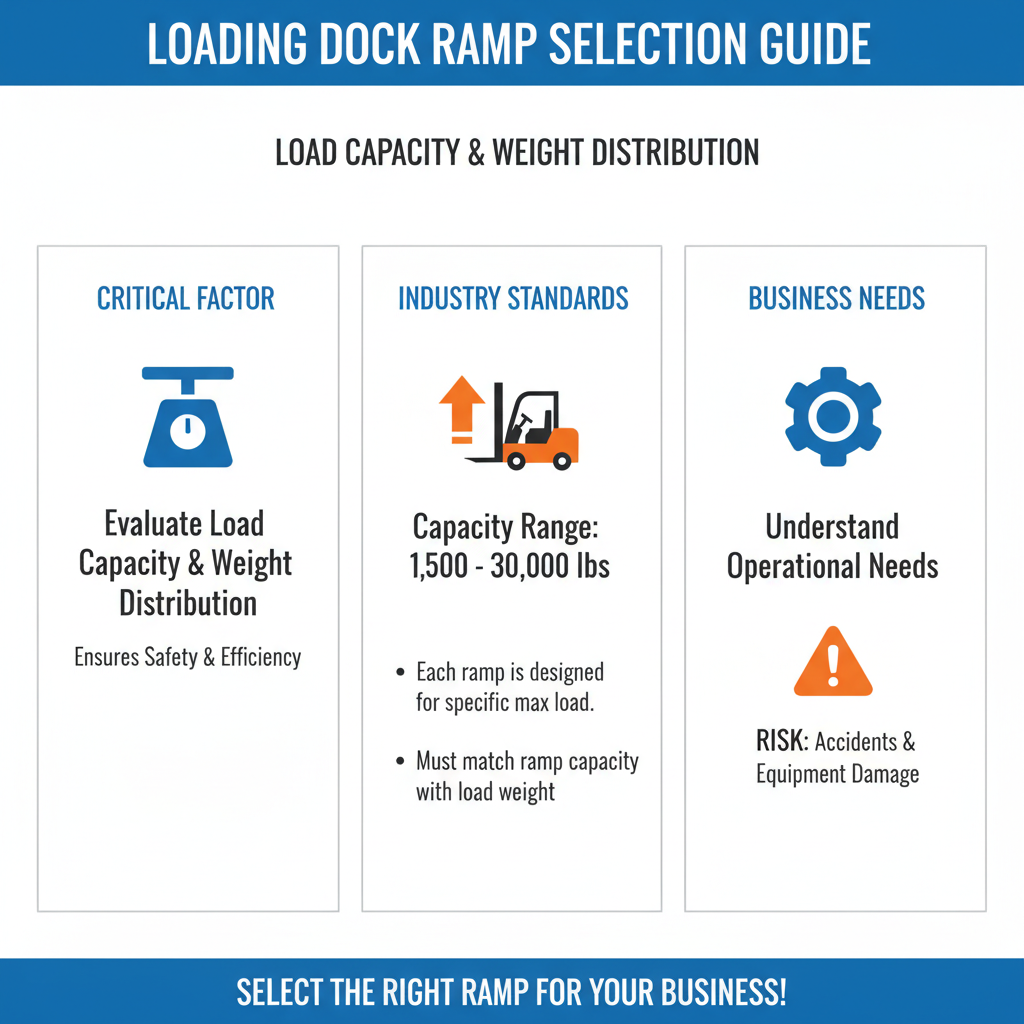

When selecting a loading dock ramp, one of the most critical factors is the evaluation of load capacity and weight distribution requirements. Industry standards indicate that each loading dock ramp is designed to handle a specific load capacity, typically ranging from 1,500 to 30,000 pounds. Understanding your business's operational needs is essential for choosing a ramp that ensures safety and efficiency during loading and unloading processes. Failing to match ramp capacity with the weight of your loads can lead to accidents and equipment damage.

Tip: Always consult the manufacturer’s specifications and consider the maximum load your business will handle. Gather data on the heaviest items you transport to avoid underestimating your requirements. Moreover, proper weight distribution is vital; unevenly distributed loads can cause instability, increasing the risk of tipping. Professional data indicates that ramps with a wider platform can significantly enhance stability during operation.

It's advisable to conduct a thorough assessment of your warehouse layout and operations to determine the appropriate ramp length and incline. Many businesses benefit from using loading dock ramps designed with adjustable heights, which cater to various vehicle types. By implementing these considerations, you ensure seamless operations and a safer environment for your employees and goods.

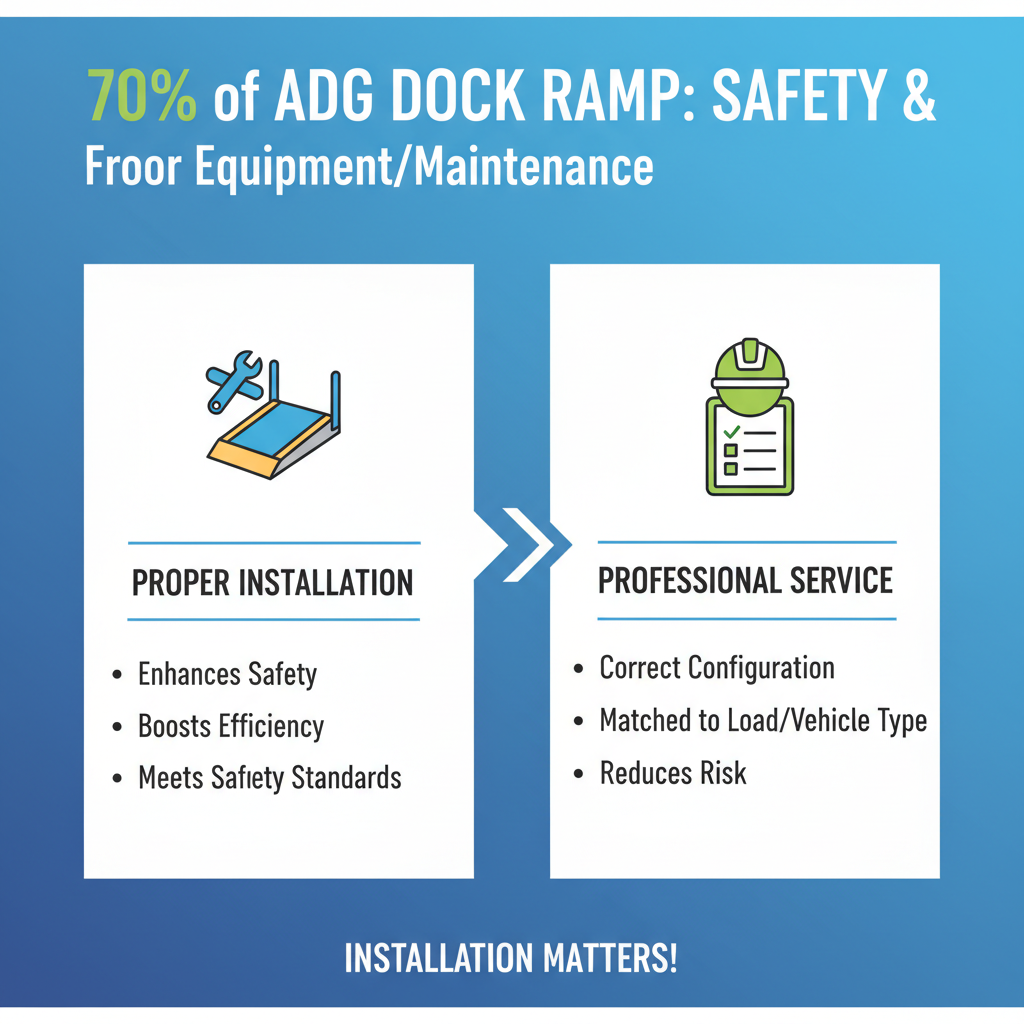

When selecting the right loading dock ramp for your business, understanding the importance of proper installation and maintenance is crucial. Industry reports indicate that 70% of loading dock accidents can be traced back to inadequate equipment and maintenance practices. Ensuring that your ramp is installed correctly not only enhances safety but also increases operational efficiency. Utilizing a professional installation service can help meet safety standards and ensure the ramp is configured to handle the specific load capacities and vehicle types that your business employs.

In addition to installation, regular maintenance is essential to prolong the lifespan of your loading dock ramp. Industry studies reveal that preventative maintenance can reduce repair costs by up to 30%. Routine inspections should focus on checking the ramp’s surface for wear and tear, ensuring hydraulic systems function properly, and examining any safety features, such as guardrails and non-slip surfaces. Implementing a maintenance schedule tailored to your ramp's usage will contribute significantly to minimizing hazards and maximizing productivity at your loading dock.

When selecting a loading dock ramp, prioritizing safety features and compliance standards is essential for any business. According to the Occupational Safety and Health Administration (OSHA), improper loading practices result in nearly 25% of forklift-related accidents. Therefore, a ramp with non-slip surfaces, proper weight limits, and robust edge safety systems can greatly reduce workplace injuries. Furthermore, compliance with local and federal regulations, such as the Americans with Disabilities Act (ADA), is crucial not just for safety but also for legal accountability. A well-designed ramp should be accessible to all users, ensuring that it aligns with industry standards while enhancing functionality.

In addition to safety features, understanding the evolving compliance landscape is vital. Recent insights from the National Safety Council highlight that companies adhering to up-to-date compliance measures can reduce workplace accident rates by up to 40%. As new technologies—like agentic AI—begin to shape safety protocols, businesses must remain vigilant in integrating these advancements into their operations. Ensuring compliance with health and safety regulations, particularly for equipment like loading dock ramps, can protect not only workers but also the business’s bottom line, ultimately creating a safer and more efficient workplace.